Interface Detection

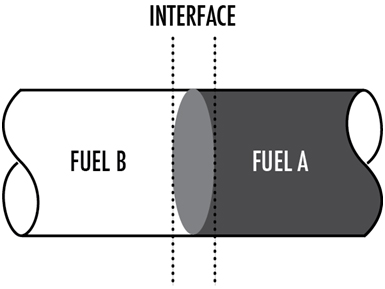

The basic concept of interface detection is simple: detect and direct the flow of different batches of refined fuels through pipelines. The implementation, however, can be very complicated. Batches of product arrive at pipeline terminals with interface between each batch. The goal of interface detection is to time the switching or cut of the incoming product in such a way that delivers the maximum quantity of product to customers without downgrading the quality of the product.

Inaccurate interface detection leads to an increase in both downgraded product (i.e., selling 91 octane as 85) and transmix, (i.e. a mixture of diesel and gasoline) which requires storage and additional refining. Both significantly cut into the profit margins on delivered product.

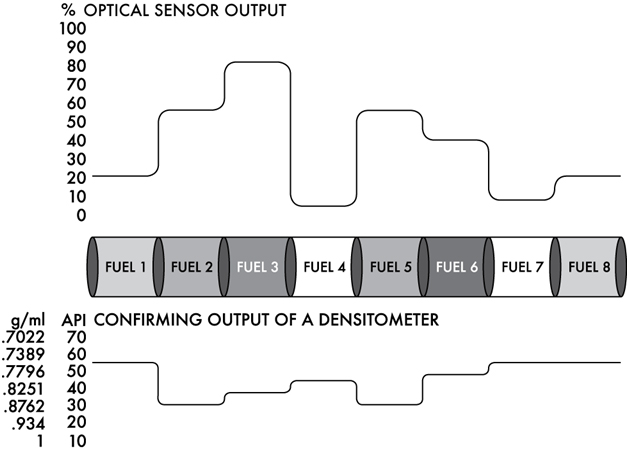

Historically, the most common method of interface detection was the use of densitometers. Most metering stations contain an existing densitometer. Measured shifts in product gravity from metering station densitometers combined with flow rate data can be used to make switching decisions downstream. In addition to metering stations, they can be installed on analyzer loops to be used specifically for interface detection

Where Densitometers Fail

Today's specialty fuels such as ULSD, often feature minute differences in density, creating difficulties for interface detection by conventional means. In addition, fluids may be dyed to indicate ownership. In such a case, two consecutive batches of diesel might differ in color, but have exactly the same density and be undetectable by conventional means.

Optical Interface Detection

Newer technologies such as optics provide opportunities for more accurate interface detection for all fuels, including specialty and dyed fuels. Optics (refractive index measurement) relies upon the ability of the fluid to absorb light rather than the fluid’s density. Typically, these sensors use fiber optic technology to emit light into the fluid. Different fluids will absorb light in different ways. The unabsorbed light is captured in a return fiber optic loop and measured, creating an optical signature for each fluid. Optical sensors are highly sensitive and respond almost immediately to fluid changes, allowing operators to make extremely accurate cuts. They can be inserted into the main line or on an analyzer loop.

Optical vs. Densitomer

Which Technology Should You Use?

The determination as to which technology is appropriate for a specific installation depends on a number of factors. These include:

- Initial cost

- Maintenance costs including man-hours

- Systems already in place such as densitometers at metering stations

- Types of fuels in the pipeline

- Training required to implement the technology

- Ability to automate interface detection

- Installation availability, i.e., mainline, analyzer loop, flanges, taps, etc.

- Ability to pig the line without sensor removal

Multiple sensor installations

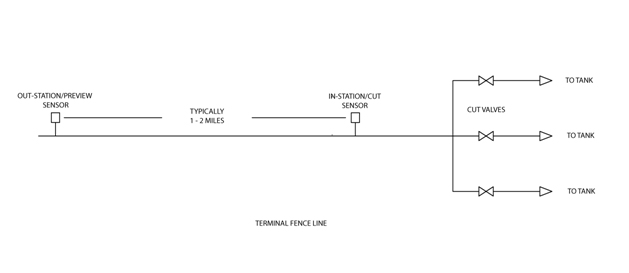

With the minute differentiations in many of today's specialty fuels, many pipeline operators choose to install multiple sensors of the same type at different locations in the pipeline. By installing a preview sensor one to two miles upstream of the terminal fence line, operators have the data and time to optimize the batch cut at a second, in-station sensor. This method reduces the potential for error and increases the operator’s confidence in their decisions. In addition, it gives the operator the time to resolve any issues that may arise during a critical interface.

© Copyright 2025 optical-interface-detector.com